Products

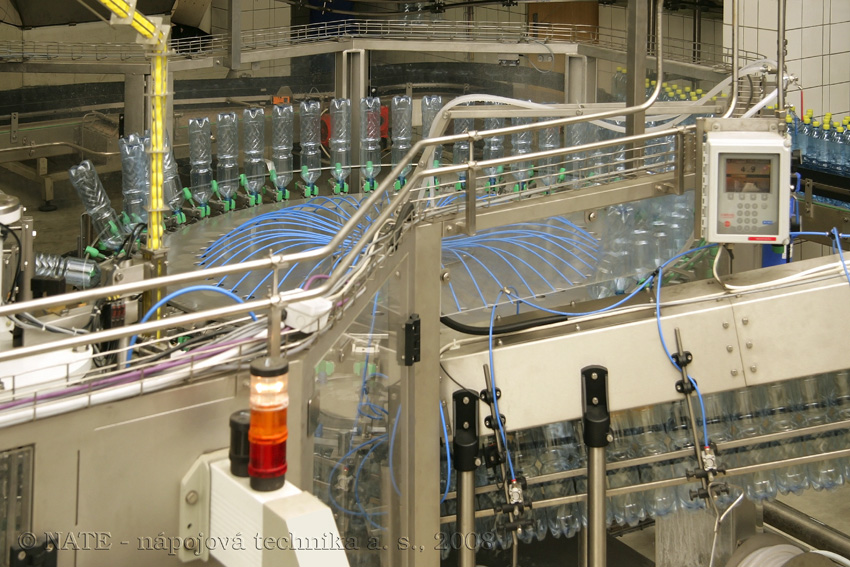

Pet lines

Output – up to 30 000 bottles/hour (depending on bottle format)

Bottle format: 0.5 – 2.5 l

References:

BOHEMIA HEALING MINERAL WATERS CZ a.s.

A great challenge for us was the supply of a complete filling line for filling mineral water into glass and PET bottles with the capacity of 4200 bottles per hour for our customer, BOHEMIA HEALING MINERAL WATERS CZ, a.s., with the production plant in BГlina.

Prior to the supply proper of the new filling technology it was necessary to prepare water management in accordance with current standards. The most up-to-date system of captation includes a thickening matrix for ZajeДЌickГЎ hoЕ™kГЎ voda with a new aseptic filler which meets any future requirements on hygienically sound operation. VERABLOK 20/24/6 filler with overpressure filling is installed in the facility. All these conditions contribute to that the mineral water never leaves its natural pressure conditions and will be transported to your table without any contact with atmospheric pressure. Together with a new range of glass bottles of dark cobalt glass it means that now BГlinskГЎ kyselka is available at the highest quality in the entire history of filling.

Line assembly:

- blowing machine OPTIMA 4

- compressor station

- bottle filler VERABLOK 20/24/6

- inspection equipment EXAN LEVEL - level checking

- labelling machine MODULAR - PLUS PE

- date stamping equipment

- packaging machine DIMAC sta@r one

- bottle conveyors

- carrying handle applicator

- volume blender of drinks - OSN 5

- herb extract applicator

- central cleaning station CIP

- depalletizer of new glass bottles NMDm 1000 R

- line distributor

- wrapping machine

- storage tank

- water management

Interesting facts about the line

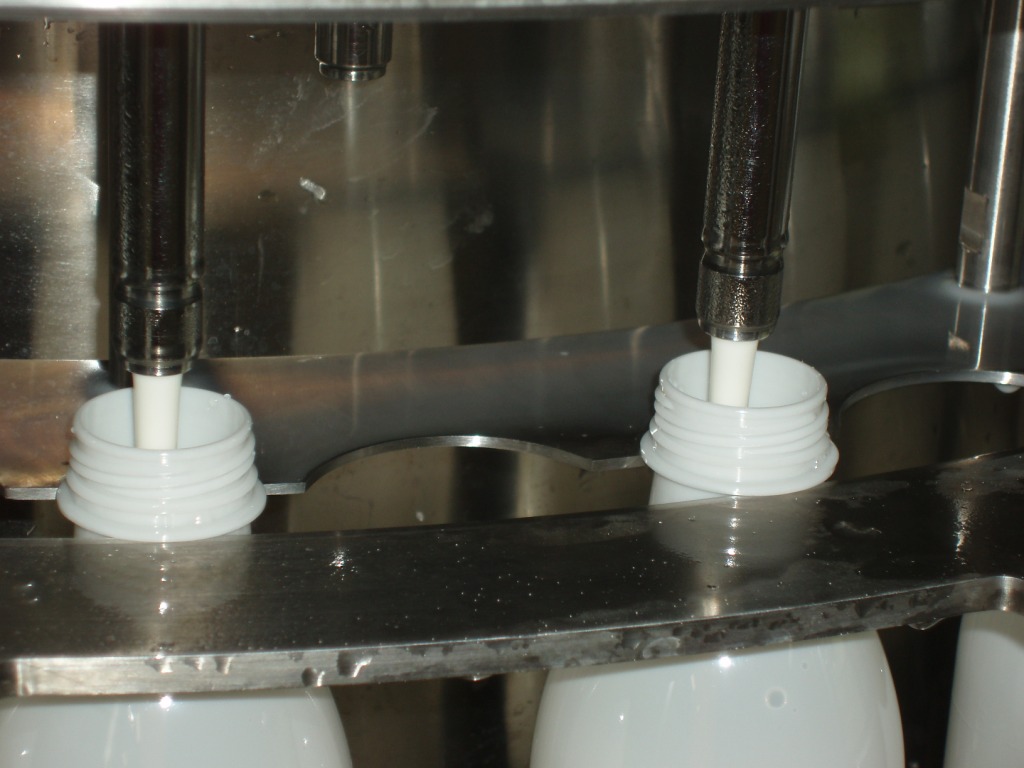

- Bottle filler VERABLOK 20/24/6

- overpressure filler with rinser and screw cap closing machine

- ULTRA CLEAN design

- bottle assortment: glass (0.25; 0.75l)

PET (0.5 l; 1.0 l) - decentralized drive technology used technology -> easy cleaning of machine surface

|

|

OndrГЎЕЎovka a.s., OndrГЎЕЎov plant, Czech Republic

- Complete filling line for filling non-carbonated and carbonated water into 1.5 l PET

Line output: 12 000 BPH

Filled beverage: non-carbonated and carbonated water

Year of delivery: 2012 - Complete filling line for filling non-carbonated and carbonated water into 1.5 l PET

Line output: 16 000 BPH

Filled beverage: non-carbonated and carbonated water

Year of delivery: 2008

Complete filling line for filling non-carbonated and carbonated water into 1.5 l PET

Line output: 12 000 BPH

Filled beverage: non-carbonated and carbonated water

Year of delivery: 2012

Delivered equipment:

- PETBLOK 40/64/8 filler

- Checking device - incompletely filled and opened bottles behind the filler - Exan Level 1.0

- DLN bottle conveyor

- Package conveyors

- Air conveyors

- OSN 20 volumetric beverage mixer

- SBO 8/10 blowing machine

- TSP 3 CLP packing machine

- Palletization

- DT System foaming

- Dry lubrication

- Pallet labelling machine

- Line distributor

Complete filling line for filling non-carbonated and carbonated water into 0.3 l glass bottles

Line output: 16 000 BPH

Filled beverage: non-carbonated and carbonated water

Year of delivery: 2008

Delivered equipment:

- 48/80/10 filler

- Air conveyors

- DLN bottle conveyors

- Package conveyors

- Checking device - incompletely filled and opened bottles behind the filler - Exan Level 1.0

- Labelling device

- Packing machine

- Palletization machine

- Conveyor control and monitoring

- Blowing device

- OSN Volumetric beverage mixer

|

|

Delivery to Georgia

- Complete filling line with a capacity of 16 000 BPH for filling beer into 1.5 l PET,

12 000 BPH for filling beer into 2.0 l PET and 9 000 BPH for filling beer into 2.5 l PET - Complete filling line with a capacity of 14 000 BPH for filling beer and flavoured water into 0.5 l glass

Complete filling line with a capacity of 16 000 BPH:

- PETBLOK 48/80/10 LT

- Checking device - incompletely filled and opened bottles behind the filler - Exan Level

- DLN bottle conveyor

- DPN package conveyors

- Air conveyors

- CM central dry lubrication

- Rollfed labelling device

- Palletization

- DT System foaming

- Dry lubrication

- Pallet labelling machine

- Line distributor

- Electrical equipment

- Packing machine

- Handle applicator

- Drying machine

Complete filling line with a capacity of 14 000 BPH:

- VERAL 50/10 filler

- ATHENA 18/18.3 bottle washer

- Closing machine

- Checking device

- Complex bottle checking in front of the filler - EXAN 08 CCD

- Check for incompletely filled and opened bottles behind the filler - EXAN Level - DLN bottle conveyors

- DPN package conveyors

- Labetta labelling device

- Packing machine

- Automatic CIP station

- MP 2000 case washer

- NAPAK 2 loader

- NAPAK 2 unloader

- Palpack 2/P palletization

- Palpack DEPS depalletization

- Case depalletization

- Tunnel pasteurizer

- Drying machine

|

|

MlГ©kГЎrna ValaЕЎskГ© MeziЕ™ГДЌГ, spol. s.r.o., Czech Republic

Filling line for milk into 1.0 l PET bottles

Line output: 4 500 BPH

Filled beverage: milk

Delivered equipment: PETBLOK 24/24/6 filler, LITO3S blowing machine, PET bottle conveyors, Package conveyors

Year of delivery: 2007

TO ASK OR ADVICE?

Do not hesitate to contact us