DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

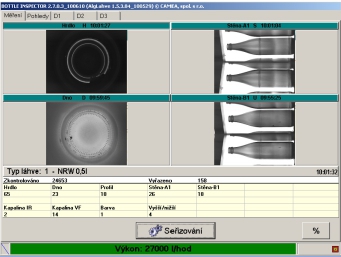

Inspection equipment

To inspect empty and full bottles – glass and PET, crates, glasses etc.

- Design ranging from the simplest equipment installed on a conveyor all the way to a fully equipped line inspector with inspection of connected conveyors

- Elimination of defective bottles to a multi-row accumulation conveyor or into containers

- Possibility to sort according to defect

- Output up to 60 000 bottles/hour

Output range:

- Glass: 1 – 60 000 l/hour

- PET

- 0,5 l: 30 000 l/hour

- 2,0 l: 18 000 l/hour

Bottle format:

- Glass: 0,25 – 1,0 l

- PET: 0,3 – 2,5 l

- Gallons

Inspection prior to filling:

|

|

|

|

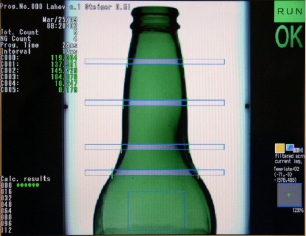

Inspection during the filling process

- Height of level and position of drink

- Presence of a cap

- Presence of a label and its position

- Presence of data

- Vacuum in the glass

Inspection methods:

- Optical with CCD camera scanning

- Optic sensors

- High-frequency

- Infrared rays

- Inductive

- Colour TFT flat monitor with the option to monitor the equipment visually, report defects

- Alignment and data archiving with touch screen control

- Remote administration via the internet, option to interconnect with the customer's information system

Other options for inspecting labels:

- Option to install in the labelling equipment

- Crate inspection (load completeness, entirety, colour)

- Other equipment according to operating needs