DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

MG - KEG barrel washers

For washing the outer surface of normally dirty KEG barrels.

Machines of the MG series are fully automatic and are produced in a standard all-stainless-steel design.

The main parts of the machines:

- barrel conveyors

- driving and driven cylinders (for the stabilisation and the rotation of the barrels)

- upper, lower and side brushes

- spraying and rinsing nozzles

- tub with steam heating

Description of the function:

- the process of moving the barrel, the washing of the barrel and its exit from the washer is fully automatic

- the barrel stoppers on the inlet side of the washer separate the barrel, which is then transported into the washing area

- into the washing area

- in the washing space the keg begins to spin after the top, side and bottom washing brushes are applied to it

- an appropriate setting for brushes and nobles ensures the perfect cleaning of the external parts of the barrel, including spraying the filling valve

- prior to its exit from the washer, the barrel is sprayed with the rinsing water (so-called super rinse)

- the temperature of the washing liquid is adjustable in the interval between 0 - 60°C

- another adjustable element is the duration of the washing of the individual barrels

Technical advantages:

- steam heating with automatic control of the temperature set

- the movement of the barrels in the washer is ensured by the self-propelled lamellar conveyor

- the washer washes all types of commonly used KEG barrels with the volumes 20 l, 30 l and 50 l and a range of diameters from 360 – 405 mm and a height of 300 - 600 mm

Performance range:

| Type | Performance | Type of machine |

|

| MG 120 | 120 | barrels per hour | automatic |

| MG 200 | 200 | ||

| MG 300 | 300 | ||

Selected references:

- Chodovar spol. s.r.o., ChodovГЎ PlanГЎ, Czech Republic - MG 120

- Pivovar ChotД›boЕ™ s.r.o., ChotД›boЕ™, Czech Republic - MG 120

- DE CJSC Obolon Krasylivske, Krasyliv, Ukraine - MG 120

|

|

MB - Barrel washers

Washing inner and outer surfaces of commonly contaminated plastic packaging.

Machines of the MB series are fully automatic and are produced in a standard all-stainless-steel design.

The main parts of the machines:

- Washing box

- Reservoir

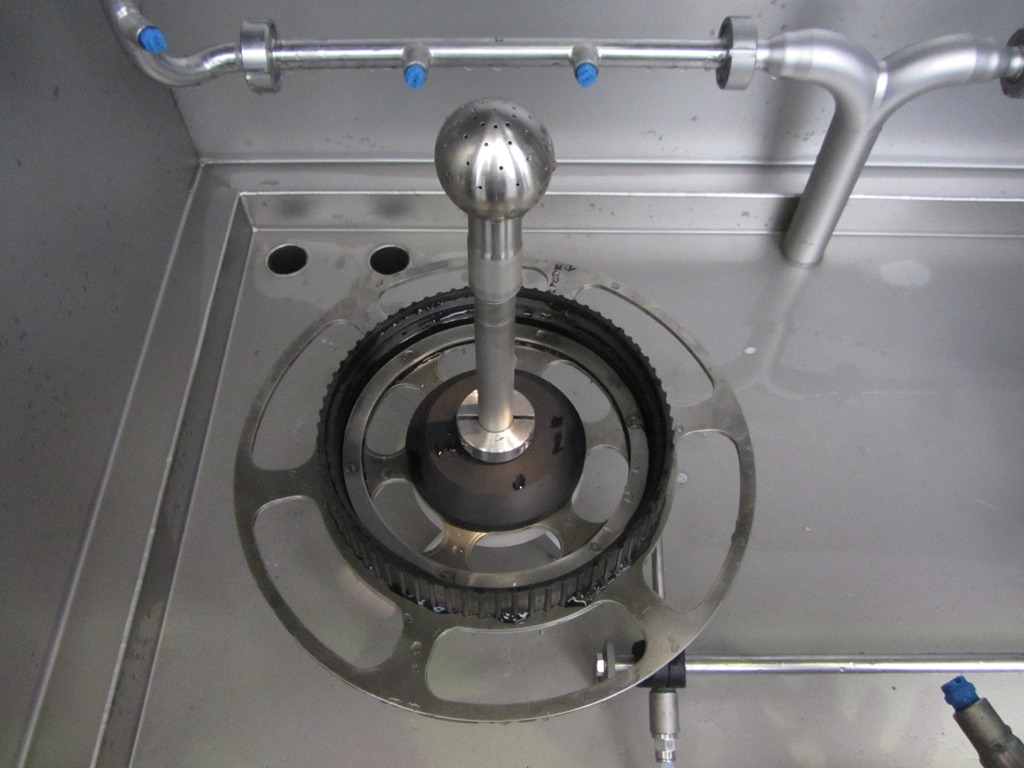

- High-pressure pump

- Rotating washing head

Description of barrel washer:

- Frame structure with a washing box

- Barrels are sprayed with nozzles and washing heads

- Washing is divided into washing the inner and outer surfaces

- Hot water is used that is supplied from the reservoir, which is a component of the washer

- The level of the washing solution is controlled by a float valve with automatic refill to the required level

Performance range:

- Performance from 40 to 80 barrels per hour

- Adjustable time period based on the degree of contamination

Selected references:

- KГЎvoviny, a.s., Pardubice, Czech republic - MB 02

|

|