DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

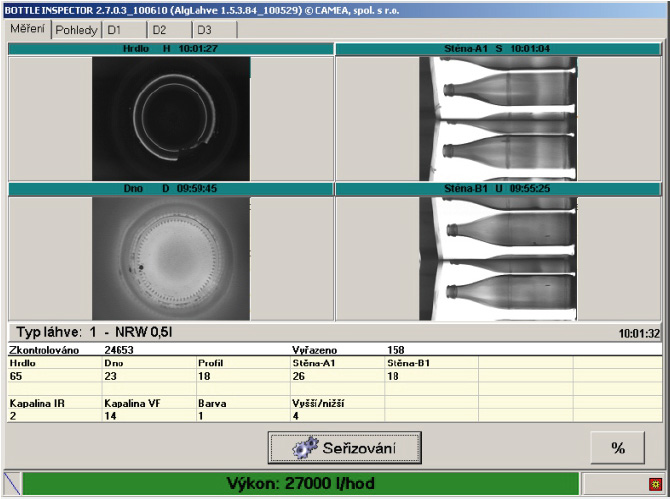

Complete inspection of bottles before filling - Exan 08 CCD

Use:

- for glass bottles that are washed by the bottle washer

- to check the cleanliness of the bottoms, walls, shapes and colours of bottles

- entirety of bottleneck mouth

- to detect residual liquid, remains of lye film

- to detect taller or shorter bottles – including toppled over bottles

- output range up to 55.000 bottles/hour

Description of function

- to check the bottoms, necks and walls of bottles on the basis of CCD cameras and specialised evaluation software

- defective bottles are automatically eliminated onto a multi-row accumulation conveyor

- high-frequency check of liquids, higher sensitivity for bottles containing lye than for bottles with water, reliably also detects lye film

- additional infra-red liquid inspections, highly reliable for larger volumes of liquid

- easy and simple to adjust without spare parts, using fast mechanical and electronic alignment

- to restrict the right to operate the equipment, more elimination, sorting of unusable bottles into the waste (with a different height or damaged neck mouth)

|

|

|

Design options

- additional bottle colour inspection

- equipped with selected functions only

- design and layout design according to the customers needs

- other functions according to the customers needs (consultation required)

Other equipment properties

- colour TFT flat screen with the option to monitor the equipment visually

- report defects, alignment and data archiving with touch screen control

- remote administration via the internet

- automatic control of the precision to eliminate defective bottles

- automatic control of the output and adjacent conveyors

- option to interconnect with the customers information system

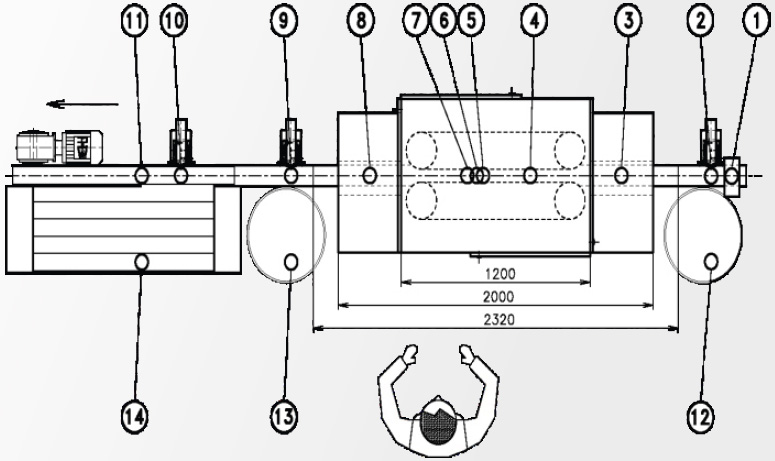

Machine layout with typical placement of control functions

- detection of taller, shorter and toppled over bottles,

- eliminator of taller and shorter bottles,

- wall and bottle shape inspection – input unit,

- bottle neck inspection,

- bottle bottom inspection,

- infra inspection of residual liquid,

- V.F. inspection of residual liquid,

- bottle wall inspection – output unit,

- eliminator for eliminating bottles with damaged necks,

- eliminator – on the table (bottles with dirty bottoms and walls, with residual liquid, wrong shaped bottle),

- inspection of correct bottle elimination,

- container for taller, shorter bottles,

- container for bottles with damaged necks,

- table (accumulation conveyor) for accumulating other defective bottles.

Example of solution

- Litovel brewery, 0.33 and 0.5 l bottles, output 36.000 bottles/hour

- PepsiCo, Prague plant, 0.25 l bottles, output 24.000 bottles/hour

- PepsiCo, Toma Teplice nad MetujГ plant, 0.3l bottles, output 18.000 bottles/hour

- Piwniczanka mineral water bottling factory - Poland, 0.33 l bottles, output 18.000 bottles/hour

- Jihlava brewery - K-Brewery, 0.5 l bottles, output 23.500 bottles/hour

- Strakonice brewery, 0.33 and 0.5 l bottles, output n 18.000 bottles/hour

- NГЎchod brewery, 0.33 and 0.5 l bottles, output n 24 000 bottles/hour

- ДЊeboksary brewery - Russia, 0.33 and 0.5 l bottles, output 25.000 bottles/hour

- Kilikia Jeveran brewery - Armenia, 0.33 and 0.5 l bottles, output 36.000 bottles/hour

- Steiger Vyhne brewery - Slovakia, 0.33 and 0.5 l bottles, output 24.000 bottles/hour

- JCS Georgian Beer Company - Georgia, 0.5 l bottles, output 18.000 bottles/hour

- AGROFIRMA TГ‹RVETE - Latvia, 0.5 l bottles, output 7.000 bottles/hour

Document to download:

|

|