Products

Filling carbonated and non-carbonated drinks

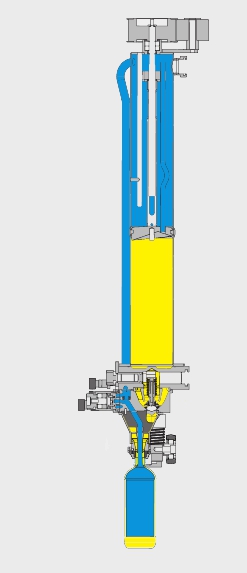

Filling method: Overpressure and pressure-free level filling

General principle of filling:

Liquid from the filler tank runs into the bottle down ist wall. Air from the bottle is siphoned off by an air tube. When the level of liquid in bottle reaches the nozzle mouth of the air tube, filling is teminated.

Overpressure level filling:

It is possible to fill glass and PET bottles with beer, mineral water, soft drinks, beer, sparkling wine and other carbonated beverages, as well as with non-carbonated beverages and liquids.

- The overpressure method allow the bottling of carbonated beverages without the undesired release of Co2 from the beverage

- Filling is carried out under a CO2 or N2 controlled atmosphere with guarantees retention of the high quality of the beverage

Filling to glass bottles:

- For bottling of beer, facilities are avaible with both retain the faste quality and increase the O2 in the beverage (0,03 mg/l for 0,5l glass bottle)

- Foaming - this reduces the volume of air in the space of the bottle neck (0,6 mg/l for a 0,5 l glass bottle)

Filling to PET bottles:

- The construction of a filler with support from underneath permits the filling of both glass and PET bottles on one machine

- If the requirement is only for filling PET bottles, the manipulation of bottles in the machine is carried out by a grip on the bottle neck - adjustment of the machine in the event of switching to another format of bottles is simplified in this manner

- Displacement of air from the bottle before filling is carried out by irrigation of bottle - intake of O2 during filling 0,08 mg/l for 1,5 l PET bottle

- Foaming - this reduces the volume of air in the neck space of the bottle (0,8 ml for 1,5l bottle)

Filling of cans:

- Can filler of our construction permit the filling cans and glass bottles on one machine

- Application of inert gas prior to capping

Non-pressurised level filling

Single-chamber filling:

- Filling of wine, spirits and low viscosity non-carbonated liquids

- Atmospheric pressure or a light under-pressure is maintained above the liquid in tank

Double-chamber filling:

- Filling of juices, syrups, edible oils and other non-carbonated liquids of higher viscosity

- The filler tank consists of two separated chambers, one with the liquids to be filled and another, to which the air is evacuated from the bottle during filling,where it is facilitates the filling of liquids of higher viscosity

Document to download:

|

|

Filling non-carbonated drinks

Filling method: Volume filling with a flow meter

Filling options:

- still water

- juice, natural juice with fibre

- ice tea

- dairy-based beverages, drinks with higher viscosity (kefir, acidophilus milk)

- filling glass and PET bottles

Basic principles of filling:

- the drink flows into the bottle into the valve of a tube, which is fitted with an inductive flowmetre that senses the flow of fluid and transmits impulses to the control system

- once the control system registers the relevant number of impulses (volume), it closes the filling valve

- the liquid flows into the bottle – air leaves the bottle freely into the atmosphere during filling

Description of function - principle:

- neither the valve nor tube comes into contact with the bottle

- the air leaves the bottle entirely outside of the tank

- drinks with small particles can be filled

- it is possible to change the filling speed – reduction of drink foaming

- the filling valve is not affected when changing the filling volume

- minimum drink residue when operation ends

- drink foaming in a semi-septic and aseptic environment

Example of solution

Dairy ValaЕЎskГ© MeziЕ™ГДЌГ, Czech Republic - PETBLOK 24/24/6

Korenovskyy Konservno-Molochnyy Kombinat, Korenovsk - Krasnodar region, Ukraine - PETBLOK 30/30/6 ULTRACLEAN, PETBLOK 24/28/6 ULTRACLEAN

Libella Bottlers Almaty, Kazakhstan - PETBLOK 30/60/78/8 ULTRACLEAN

|

|

Filling carbonated and non-carbonated drinks into PET bottles

Filling method: Mechanical volume filling using graduated cylinders

Filling options:

- mineral water

- still water

- soft drinks

- sparkling wine

- carbonated and non-carbonated liquids

- filling to PET or glass bottles

General principle of filling:

- the liquid is released into the measuring cylinder

- from here the liquid is drained into bottles in

- a precisely pre-measured volume along the walls of

- the bottles

- air is extracted from the bottle by an air tube to

- a space outside the tank

- the filled volume is defined by adjustment of the

- height of the piston of the filling valve

Principle and parametres:

- faster speed of filling - lesser number of filling valves

- reduction of 80% in loss of beverages in the event of interruption of filling-special emptying cistern

- fast change of volumes to be filled, without the necessity to intervene with the filling valves,

- always the same volume of filled liquid in PET bottle regardless of pressure during the filling process or the quality of the PET bottles

- filling within the volume range of 0,33 l - 2,5 l,

- single - or double - evacuation for glass bottles

- irrigation of bottle - for PET bottles - and foaming permits the achieving of a low increase of O during filling

- application of inert gas (liquid N ) to the bottleneck space, after the filling of the bottle, before capping - creates protection of the beverage from oxygen activity (increasing shelf life and maintaining taste) and from hardening of the bottle prior to further manipulation (labelling, packaging and palletisation)

- in the scase on of non-carbonated beverages

Example of solution:

- Veseta spol. s.r.o., plant Litovel, Czech republic -PETBLOK 48/80/10

- OndrГЎЕЎovka a.s., plant OndrГЎЕЎov, Czech republic - PETBLOK 48/80/10 ULTRACLEAN, PETBLOK 40/64/8

- VГ„RSKA VESI AS, Varska, Estonia - PETBLOK 30/50/8

- Telemark Kildevann, Fryesdal, Norway - PETBLOK 40/64/10

- UAB „Kalnapilio-Tauro grupe”, Panevežys, Latvia - PETBLOK 48/90/10

|

|

TO ASK OR ADVICE?

Do not hesitate to contact us