DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

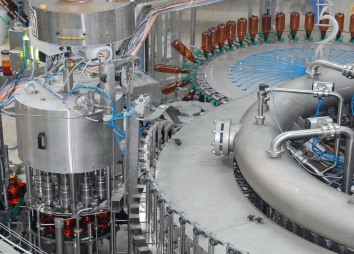

Filling carbonated drinks into glass and PET bottles

Filling method: Volume filling with a flow meter

Filling options:

- mineral water

- still water

- soft drinks

- sparkling wine

- carbonated and non-carbonated liquids

- filling to PET or glass bottles

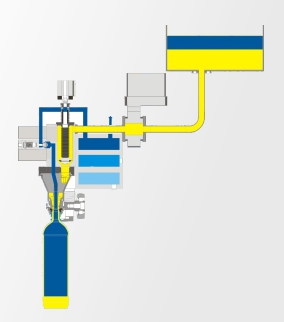

Basic principes of filling:

- after pressurising the bottle, the drink flows through a tube into the valve which is equipped with an inductive flowmeter that scans the flow of liquid and transmits impulses to the valve's control system

- after recording the relevant quantity of impulses (volume), the flow meter closes the filling valve

- the liquid pours into the bottle along the walls and while the bottle is being filed, the air is removed outside of the tank space

Principle and parametres:

- speed performance about 15-20% greater than with the mechanical volume valve

- minimum residue of the beverage after the end of the operation

- the outflow of the air from the bottle during filling is directed to another area outside the tank

- no adjustment of the valve is required when changing the size of bottle or the volume to be filled

- the filling process is controlled from the control system of the filling machine and therefore is not dependent on the current performance of the filling machine or affected by the stopping of the machine

- possibility of automatic employment of sanitation adapters

- better sanitation of the filling valve, in comparison with the mechanical volume valve (simpler mechanical design) - the design of the fluid valve cone and the valves for evacuation, pressurisation and relese of pressure, using bellows and membrane seal

Filling of sensitive beverages:

For filling of sensitive beverages the filler can be supplied with a casting and air filtration.

Spherical tank with a circular cross-section:

- Cylindrical design of the tank

- Utilisation of admission nozzles accelerates and improves the sanitation of the filler

- ostЕ™ikovГ© trysky,

- At the end of filling there remains only a minimal residue of the beverage

The Siemens SIMATIC control system SIMATIC S7 300:

- Colour touch screen 10" terminal

- Signalling of status of individual machineВґs functioning and malfunctioning (code number and description of failure) on the terminal

- Control of the machine by means of the touch- screen terminal

- Output and archiving of data for the monitoring and visualisation systems

- Remote administration and servicing through a telephone connection or via the internet

Example of solution:

- PET PACK Kft., Hungary - PETBLOK 48/80/10

|

|

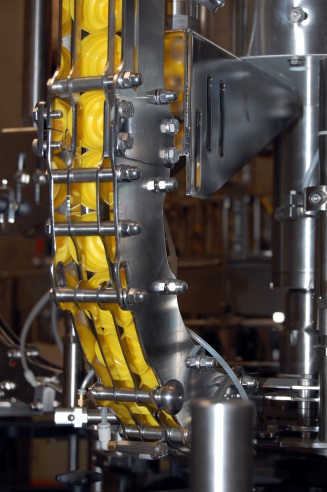

Filling carbonated and non-carbonated drinks into PET bottles

Filling method: Mechanical volume filling using graduated cylinders

Filling options:

- mineral water

- still water

- soft drinks

- sparkling wine

- carbonated and non-carbonated liquids

- filling to PET or glass bottles

General principle of filling:

- the liquid is released into the measuring cylinder

- from here the liquid is drained into bottles in

- a precisely pre-measured volume along the walls of

- the bottles

- air is extracted from the bottle by an air tube to

- a space outside the tank

- the filled volume is defined by adjustment of the

- height of the piston of the filling valve

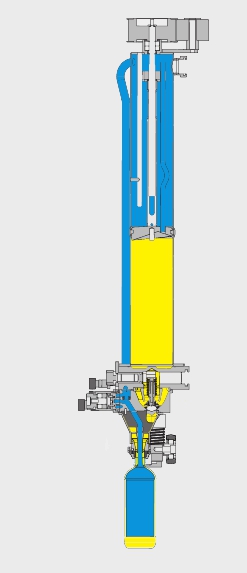

Principle and parametres:

- faster speed of filling - lesser number of filling valves

- reduction of 80% in loss of beverages in the event of interruption of filling-special emptying cistern

- fast change of volumes to be filled, without the necessity to intervene with the filling valves,

- always the same volume of filled liquid in PET bottle regardless of pressure during the filling process or the quality of the PET bottles

- filling within the volume range of 0,33 l - 2,5 l,

- single - or double - evacuation for glass bottles

- irrigation of bottle - for PET bottles - and foaming permits the achieving of a low increase of O during filling

- application of inert gas (liquid N ) to the bottleneck space, after the filling of the bottle, before capping - creates protection of the beverage from oxygen activity (increasing shelf life and maintaining taste) and from hardening of the bottle prior to further manipulation (labelling, packaging and palletisation)

- in the scase on of non-carbonated beverages

Example of solution:

- Veseta spol. s.r.o., plant Litovel, Czech republic -PETBLOK 48/80/10

- OndrГЎЕЎovka a.s., plant OndrГЎЕЎov, Czech republic - PETBLOK 48/80/10 ULTRACLEAN, PETBLOK 40/64/8

- VГ„RSKA VESI AS, Varska, Estonia - PETBLOK 30/50/8

- Telemark Kildevann, Fryesdal, Norway - PETBLOK 40/64/10

- UAB „Kalnapilio-Tauro grupe”, Panevežys, Latvia - PETBLOK 48/90/10

|

|