DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

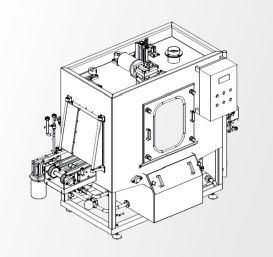

KEG barrel washers MG

Washing the outer surface of normally dirty KEG barrels.

Machines of the MG series are fully automatic and are produced in a standard all-stainless-steel design.

The main parts of the machines are:

- Barrel conveyors

- Driving and driven cylinders (for the stabilisation and the rotation of the barrels)

- Upper, lower and side brushes

- Spraying and rinsing nozzles

- Tub with steam heating

Description of function:

- The process of moving the barrel, the washing of the barrel and its exit from the washer is fully automatic

- The barrel stoppers on the inlet side of the washer separate the barrel, which is then transported into the washing area

- In the washing area the barrel starts spinning due to the application of upper, side and lower brushes

- An appropriate setting for brushes and nozzles ensures the perfect cleaning of the external parts of the barrel, including spraying the filling valve

- Prior to its exit from the washer, the barrel is sprayed with the rinsing water

- The temperature of the washing liquid is adjustable in the interval between 0 - 60°C,

Another adjustable element is the duration of the washing of the individual barrels

Another adjustable element is the duration of the washing of the individual barrels

Technical advantages:

- Steam heating with automatic control of the temperature set

- The movement of the barrels in the washer is ensured by the self-propelled lamellar conveyor

- The washer washes all types of commonly used KEG barrels with the volumes 20 l, 30 l and 50 l and a range of diameters from 360 - 405 mm and a height of 300 - 600 mm