DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

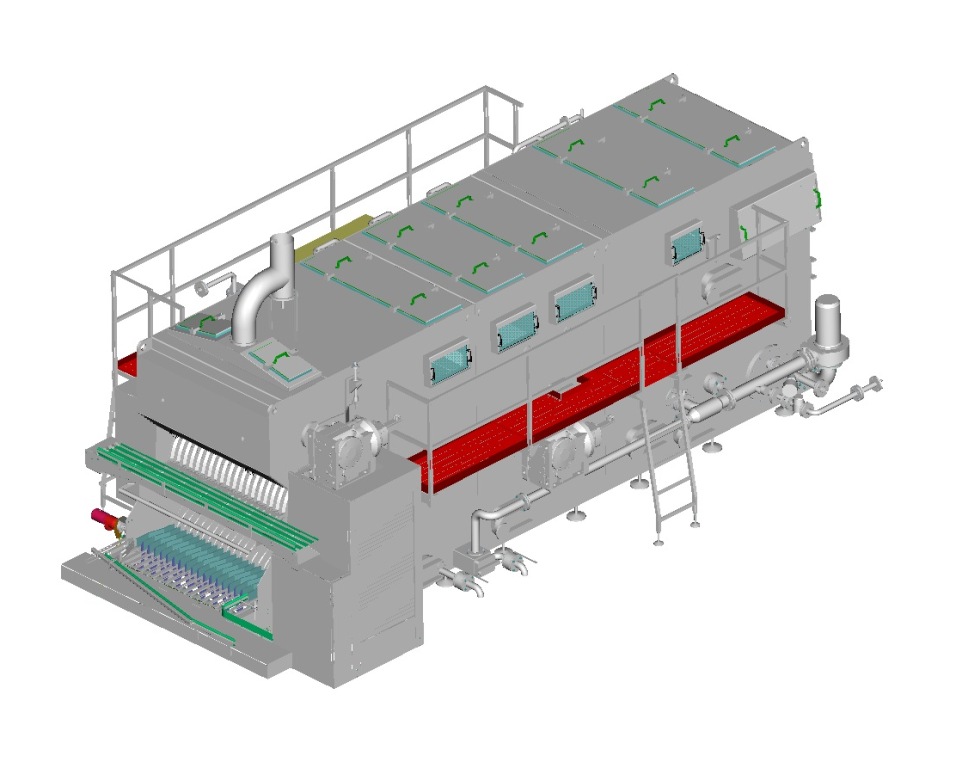

Bottle washer for low, middle and high output

Output range: 3.000 – 50.000 BPH

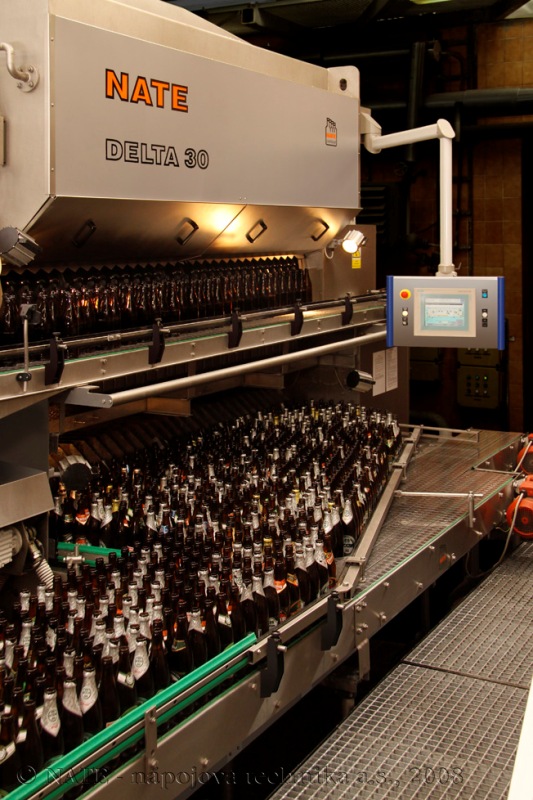

Bottle washers ATHENA, DELTA and LAGUNA with coninuous motion of bottle carriers

Single-ended and double-ended design:

- return ones (single-ended), inlet and outlet on one side, ATHENA and DELTA types

- through ones (double-ended)- inlet and outlet on opposite sides, LAGUNA type

|

Parameters:

|

Bottle washing range: Bottle dimension

|

| Group | Type | Bottle capacity/hr. (bottle volume) |

| Low capicities | Athena | 5 000 - 10 000 (0,5l) / 3 000 - 6 000 (1l) |

| Medium capacities | Athena | 12 000 - 28 000 (0,5l) / 8 000 - 20 000 (1l) |

| High capacities | Delta, Laguna | 24 000 - 50 000 (0,5l) / 17 000 - 35 000 (1l) |

- rinsing pumps pressure: 1.5 bar

- contact of bottles with washing solution: 8-12 min.

- rocking above-level lye rinsing of labels (DELTA, LAGUNA)

- active mechanism for removal of labels in the area of above-lever rinsing (DELTA, LAGUNA)

- continuous movement of bottle carriers - carriers move with constant speed, bottles are inserted and discharged during concurrent movement of bottle carriers

- control system SIEMENS S7

Bottle washers for low outputs (return washers)

Washing process:

- Pre-soaking of bottles 40 - 50°C

- Soaking in the lye washing bath 80 - 84°C

- Lye rinsing 80 - 90°C

- Emptying of lye residues from bottle bottoms

- Inside and outside rinsing with hot water 55 - 65°C

- Inside and outside rinsing with warm water 40 - 50°C

- Inside and outside rinsing with cold water 25 - 35°C

- Inside and outside rinsing with drinking water 10 - 15°C

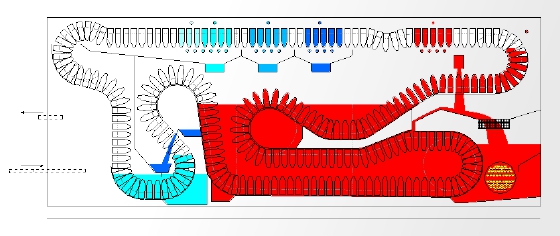

Bottle washers for medium outputs (return washers)

Washing process:

- Pre-soaking of bottles 35 - 45°C

- Pre-injection/bottle tempering 45 - 55°C

- Soaking in the lye washing bath 80 - 84°C

- Lye rinsing 80 - 90°C

- Emptying of lye residues from bottle bottoms

- Inside and rinsing with hot water 55 - 65°C

- Inside and outside rinsing with warm water 40 - 50°C

- Inside and outside rinsingwith cold water 25 - 35°C

- Inside and outside rinsingwith drinking water 10 - 15°C

Bottle washers for medium outputs (return washers)

Washing process:

- Pre-soaking of bottles 35 - 45°C

- Pre-injection/bottle tempering 45 - 55°C

- Soaking in the lye washing bath 80 - 84°C

- Lye rinsing 80 - 90°C

- Additional lye inside rinsing 65 - 75°C

- Emptying of lye residues from bottle bottom

- Inside and outside rinsing with hot water 55 - 65°C

- Inside and outside rinsing with warm water 40 - 50°C

- Inside and outside rinsing with cold water 25 - 35°C

- Inside and outside rinsing with drinking water 10 - 15°C

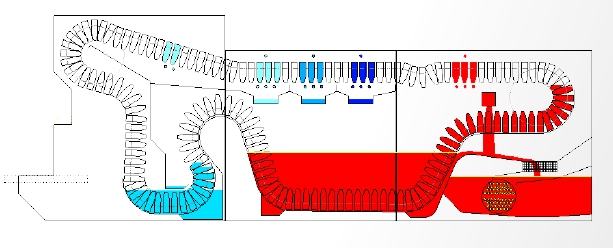

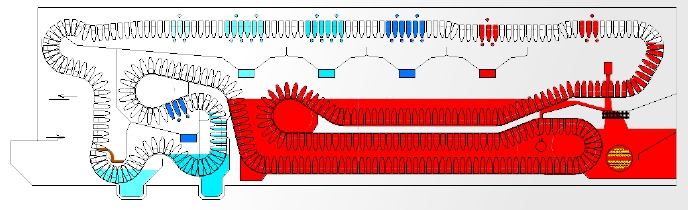

Bottle washers for high outputs (return washers)

Washing process:

Emptying of residuals from bottles

- Pre-soaking of bottles 30-40°C

- Pre-soaking of bottles 40-50°C

- Pre-injection 50-60°C

- soaking in the lye washing bath 80-84°C

- Lye rinsing 80-90°C

- Additional lye inside rinsing 65-75°C

- Inside and outside rinsing with hot water 55-65°C

- Inside and outside rinsing with warm water 40-50°C

- Inside and outside rinsing with cold water 25-35°C

- Inside and outside rinsing with drinking water 10-15°C

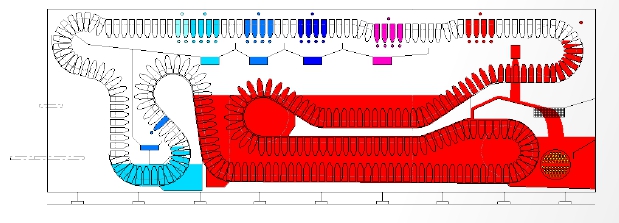

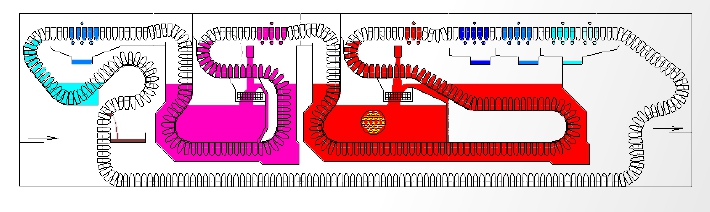

Bottle washers for high outputs (through-feed washers)

Washing process:

- Emptying of residuals from bottles

- Pre-soaking of bottles 30-40°C

- Pre-injection 50-60°C

- Soaking in the lye washing bath I. 75-80°C

- Inside and outside rinsing with lye I. 75-85°C

- Soaking in the lye washing bath II. 80-84°C

- Inside and outside rinsing with lye II. 80-90°C

- Inside and outside rinsing with hot water 55-65°C

- Inside and outside rinsing with warm water 40-50°C

- Inside and outside rinsing with cold water 25-35°C

- Inside and outside rinsing with drinking water 10-15°C

Other important washer features:

- Material design: all-stainless steel, combined

- Decentralized drives

- automatic alignment of individual drives

- automatic setting of bottle inserting and discharging mechanism for various types of bottle

- defective basket detection – failure of insertion of bottles into rows with a damaged basket during normal operation, replacement of a defective basket during machine maintenance - Automatic control of drinking water consumption according to current machine output and bottle type

- Control system Siemens SIMATIC S7

- Wide range of accessories

Document to download:

|

|