DO YOU NEED

TO ASK OR ADVICE?

Do not hesitate to contact us

Products

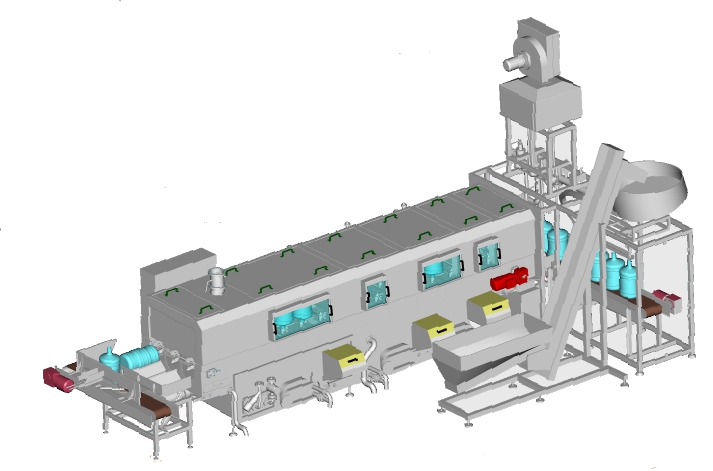

Bareltriblock – 19L barrel washing and filling

- The bottle washer and filler drive is based on stepper principle

- The screen in the residue spilling section to retain solid impurities

- Automatic operation of the machine with indication of fault conditions on the operator control panel

- Continuous level measurement in all washing zone tanks

- Filtering out impurities from washing solutions before entry to tubs

- Additional cartridge filtration of washing solutions before entry to nozzles

- Potable water saving – utilization of water from the final rinse in the inter-rinse section

- The final washing section – rinsing with product water – is sanitiable within the circuit

- Accurate filling controlled by flow meters

- Aseptic diaphragm valves to close filling valves

- Filling machine sanitization within the circuit

- Ultraclean covering for barrel filling and closing area

Sections:

- Returnable container washing

- Barrel filling and closing

- Loading and removal of full barrels at the end of the line is carried out manually

Fundamental washing procedure:

- The washer washes the barrel in several sections

- Water drip is followed by washing with an acid solution

- After inter-rinsing with water, disinfection, final washing with product water follows – this section is sanitizable within the circuit

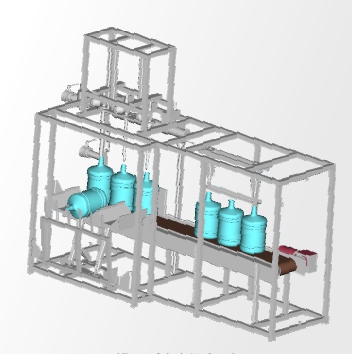

- The barrel is turned around 180° after washing and placed under the filling needles – The required volume is measured out into it

- In order to ensure maximum cleanliness during bottle filling, the filling area is covered and filtered air is forced in

- The cap is placed and pushed and sealed after filling